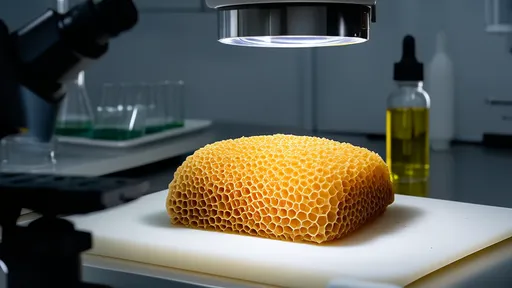

The preservation of chlorophyll in leafy greens during thermal processing has long been a challenge for both food scientists and culinary professionals. While heat treatment is necessary to ensure food safety and extend shelf life, it often comes at the cost of vibrant green color – a visual marker of freshness that significantly influences consumer acceptance. Recent advances in understanding the time-temperature relationship during blanching have revealed surprising opportunities to maximize chlorophyll retention without compromising food safety standards.

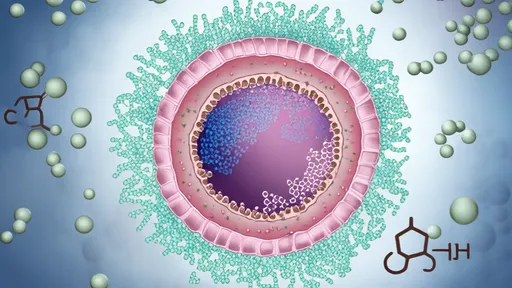

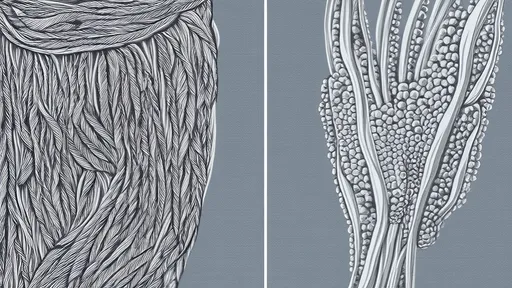

At the molecular level, chlorophyll is remarkably sensitive to heat. The magnesium ion at the center of the chlorophyll molecule can be easily displaced by hydrogen ions when exposed to prolonged heat, resulting in the formation of pheophytin – the dull olive-green compound that makes overcooked vegetables look unappetizing. However, research now shows that the duration of heat exposure plays a more critical role than temperature alone in this conversion process. Short bursts of intense heat may actually cause less chlorophyll degradation than prolonged exposure to moderate temperatures.

The concept of thermal inertia in plant tissues helps explain this phenomenon. When leafy greens are introduced to boiling water, the outer layers heat up almost instantly, but the interior temperature rises more gradually. Traditional blanching methods often keep vegetables in hot water longer than necessary to ensure the center reaches the target temperature. Modern approaches suggest that higher temperatures for shorter durations can achieve the same microbial reduction while better preserving chlorophyll through what researchers call the "thermal shock" effect.

Water quality surprisingly emerges as another crucial factor in chlorophyll retention during blanching. Hard water with high mineral content accelerates chlorophyll degradation due to the increased availability of ions that can displace magnesium. Many commercial processors now use demineralized water or add chelating agents to protect the chlorophyll molecules during the critical heating phase. The pH of the blanching water also requires careful control, as acidic conditions promote pheophytin formation while slightly alkaline conditions (pH 7-8) help stabilize chlorophyll.

Post-blanching cooling methods significantly impact the final chlorophyll content. The traditional practice of shocking blanched greens in ice water, while effective at stopping the cooking process, may actually contribute to cellular damage that leads to subsequent chlorophyll leakage. Alternative approaches using controlled ambient cooling or mild chilled water (10-15°C) show promise in maintaining both texture and color integrity. Some innovative operations employ vacuum cooling technology to rapidly lower the temperature while minimizing physical damage to the delicate leaf structures.

Seasonal variations in raw material composition add another layer of complexity to chlorophyll preservation. Leaves harvested in different growing conditions contain varying levels of natural antioxidants, cell wall structures, and enzyme activities – all of which influence how chlorophyll responds to heat treatment. Summer-grown greens with thicker cuticles often withstand thermal processing better than their more delicate winter counterparts, suggesting that processing parameters should be adjusted according to seasonal raw material characteristics.

The cutting or shredding of leaves before processing creates additional challenges for chlorophyll retention. Mechanical damage from cutting releases oxidative enzymes and exposes more surface area to heat and water. Some processors have found success with alternative approaches like whole-leaf blanching followed by gentle cutting under modified atmosphere conditions. This method reduces the immediate enzymatic onslaught that occurs when damaged cells come into contact with oxygen.

Emerging technologies like microwave-assisted thermal processing and high-pressure pasteurization offer new possibilities for chlorophyll preservation. These methods can achieve the necessary microbial reduction with significantly reduced thermal loads, potentially revolutionizing how we process leafy greens. Early studies show chlorophyll retention rates 20-30% higher than conventional blanching when using these novel technologies, though scale-up challenges remain.

Consumer education forms the final piece of the chlorophyll preservation puzzle. The food industry must communicate that slight variations in green color intensity don't necessarily indicate reduced nutritional value or quality. While chlorophyll serves as an important visual freshness marker, many nutrients remain stable even when the bright green color fades slightly. This understanding could help reduce unnecessary food waste while still maintaining high quality standards.

Looking ahead, the optimization of thermal processing for chlorophyll retention requires a systems approach that considers pre-harvest conditions, precise time-temperature control, water quality management, and innovative cooling techniques. As research continues to unravel the complex interactions between heat and plant pigments, food processors gain increasingly sophisticated tools to deliver leafy greens that are both safe and visually appealing. The ultimate goal – achieving that perfect balance between food safety and quality – may soon be within reach through these advances in understanding thermal timing.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025