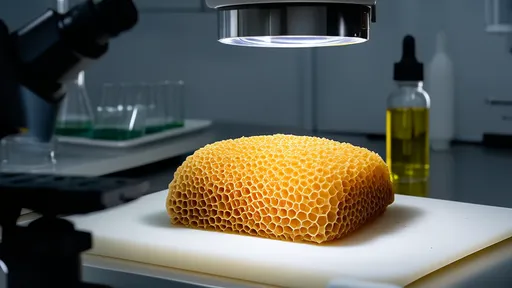

Fried foods hold a universal appeal, with their golden-brown exteriors and satisfying crunch. Yet, beneath that irresistible texture lies a complex interplay of chemistry and physics—particularly in how batters absorb oil during frying. Recent research has shifted focus to batter porosity, a critical but often overlooked factor determining oil uptake. Understanding this relationship could revolutionize how we approach fried food production, balancing indulgence with health considerations.

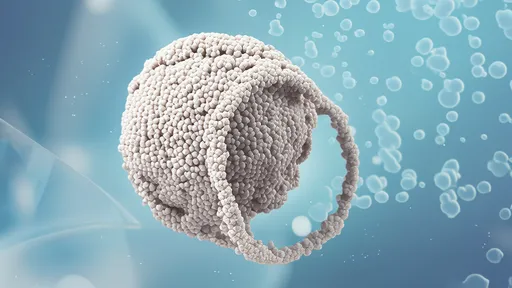

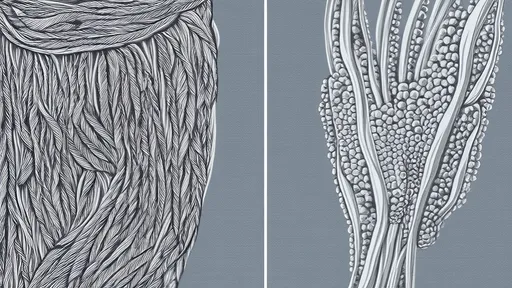

When food meets hot oil, a rapid sequence of events unfolds. Moisture within the batter vaporizes, creating steam that escapes through microscopic channels. These vacated spaces become pores that oil subsequently infiltrates. The size, distribution, and connectivity of these pores dictate just how much oil clings to the food post-frying. Studies using micro-CT scanning reveal that batters with larger, interconnected pores exhibit significantly higher oil absorption compared to those with finer, isolated cavities.

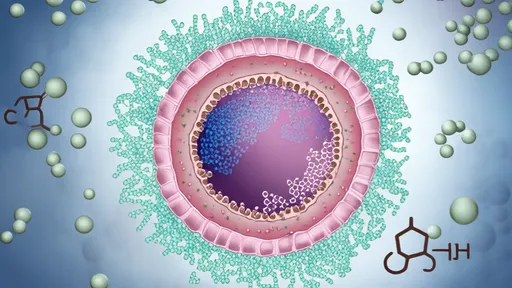

Batter composition emerges as a key architect of porosity. Proteins like gluten and starches from wheat or rice undergo distinct gelatinization processes during frying. While gluten forms elastic networks that trap steam, starches swell and eventually rupture, creating escape routes for moisture. The ratio between these components determines pore structure—higher starch content typically yields more porous, oil-prone crusts. Meanwhile, hydrocolloids like methylcellulose can strategically modify this architecture by forming thermal gels that limit oil penetration.

Frying parameters dramatically influence the pore narrative. Oil temperature operates on a double-edged sword: sufficiently high heat (180-190°C) creates a rapid moisture barrier through surface dehydration, while lower temperatures prolong frying, allowing deeper oil migration. Research indicates that the first 20 seconds of frying are pivotal, as this window establishes the pore framework that will govern subsequent oil absorption. Interestingly, post-frying drainage time also plays a role—oil clinging to the surface gradually seeps into existing pores as foods cool.

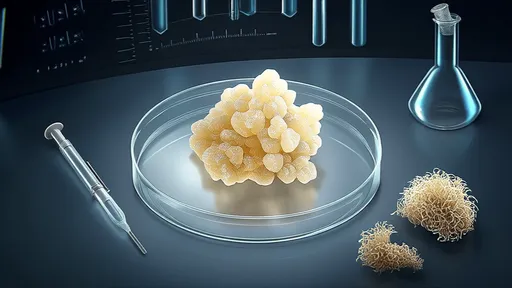

Innovative approaches are rewriting porosity management. Some food scientists are experimenting with vacuum frying, where reduced pressure lowers the boiling point of water, theoretically creating smaller, more uniform pores. Others are incorporating rice bran or pea fiber into batters—these additives introduce microstructures that redirect oil flow. Perhaps most promising are edible coatings containing nanoparticles of silica or chitosan, which create labyrinthine pore pathways that physically obstruct oil while maintaining crispness.

The health implications of porosity research are profound. By mapping how specific batter formulations correlate with oil uptake, manufacturers can engineer "lighter" versions of fried classics without sacrificing sensory appeal. This knowledge also informs home cooking—simple adjustments like maintaining consistent oil temperature or patting foods dry pre-frying can reduce oil absorption by up to 15%. As consumers increasingly demand transparency about what they eat, understanding batter porosity offers a scientific basis for more informed dietary choices.

Looking ahead, the field is ripe for exploration. Advanced imaging techniques may soon allow real-time pore visualization during frying, while AI modeling could predict optimal batter compositions for targeted oil absorption. There's growing interest in how pore structures evolve during storage, affecting that tragic loss of crispness in leftover fried foods. One thing remains certain: that delectably crispy crust we crave is far more than meets the eye—it's a marvel of edible engineering, where microscopic pores hold the key to both culinary pleasure and nutritional progress.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025